A proud provider for the transportation, agriculture, military, marine, and construction industries, McLaughlin Body Company offers aluminum, stainless steel, and steel CNC tube bending. We feature both CNC mandrel and CNC roll bending methods features include:

- Burrless Chamfer

- Flanging

- Chipless

- High Pressure and High Purity

- Sanitary

- Serpentine

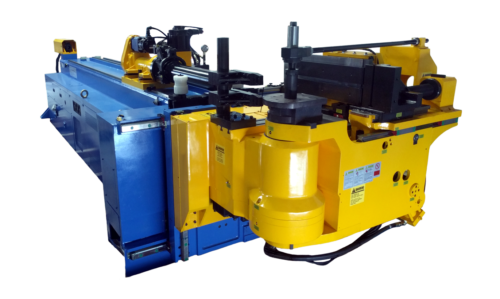

McLaughlin Body Company uses Horn CNC Machine Bend Pro precision tube bender configured for bending tight radius and difficult applications with any type or shape of material up to 140 mm x 3.75 mm.

CNC Tube Bending Capabilities

- Method

-

CNC Mandrel Bending

CNC Roll Bending

- Body Cross Section

-

Complex Geometries and Profiles

OvalRound

Square

- Maximum Outside Diameter

-

5 in

- Wall Thickness

-

Up to Schedule 80 Steel & Stainless Steel

- Maximum Tube Length

-

20 ft

- Tolerance (+/-)

-

0.005 in

- Materials

-

Aluminum

Stainless Steel

Steel

- Features

-

Burrless Chamfer

Chipless

Flanging

High PressureHigh Purity

Sanitary

Serpentine

- Additional Services Provided

-

Brazing

Crimping

Cutting

Deburring

Drilling

End TrimmingLaser Cutting Leak

Checking

Machining

Repair

Welding

- Product

-

Cab Chassis Frames

Roll Cages

- Industry Focus

-

Agricultural

Auto/Truck/Transportation

ConstructionMarine

Military

- Industry Standards

-

ISO 9001:2015

Mil-Spec Compliant

- File Formats

-

AutoCAD (DWG,DWZ)

BMP

DXF

GIF

IGES

JPG or JPEGMasterCam (MDX, MC8, MC9, SET)

PDES

PDF

Pro-E or Pro/Engineer (DRW,PRT,XPR)

SAT

SolidWorks (SLDPRT,SLDDRW,SLDDRT)